Manufacturing capabilities

SOKOL Drilling motors and tools runs the large manufacturing base (~2,5 hectares) equipped with advanced equipment, CNC milling and grinding machines and all the necessary testing stations and assembly sites.

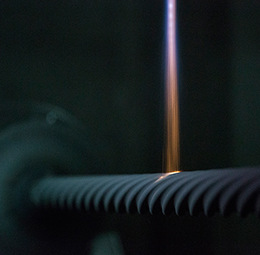

We mastered new manufacturing technology of downhole motors with low friction and corrosion-resistant coatings for salt-saturated and aggressive mud.

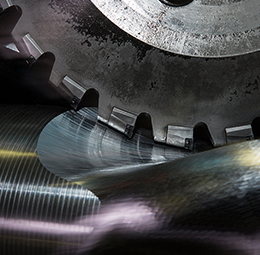

Our high-performance CNC machinery from leading global producers give new manufacturing opportunities and help us meet the highest industry requirements for variety of applications in directional and horizontal drilling.

The annual production of rotors, stators and drilling motors of all sizes:

- 600 motors with adjustable bent housing, 1200 rotors, 900 stators

- Long rotor production (up to 6500 mm) on CNC milling and grinding machines

- Rotor production with low friction and corrosion-resistant coatings

- Long stator production (up to 6500 mm) on high-performance Desma injection machine

- In cooperation with Russian Academy of Sciences we formulated new math models which help us select fit-for-purpose elastomer compounds and injection parameters

- New elastomers developed for all types of mud and temperatures

- Rotors and stators repair technology

- ID honing up to 5000mm long

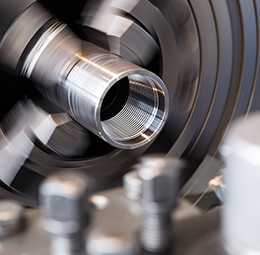

- 4-axis machining centers from Doosan and several turn-mill centers

- Deep-hole drilling machine up to 5000 mm

- Machining of non-magnetic steel with manufacturing technology of non-magnetic rotary drill stem elements in accordance with the latest industry specifications

- Welding and hard facing technology for reducing wear, erosion and corrosion on all types of drilling tools

- Jar-testing machine