Elastomers & coatings

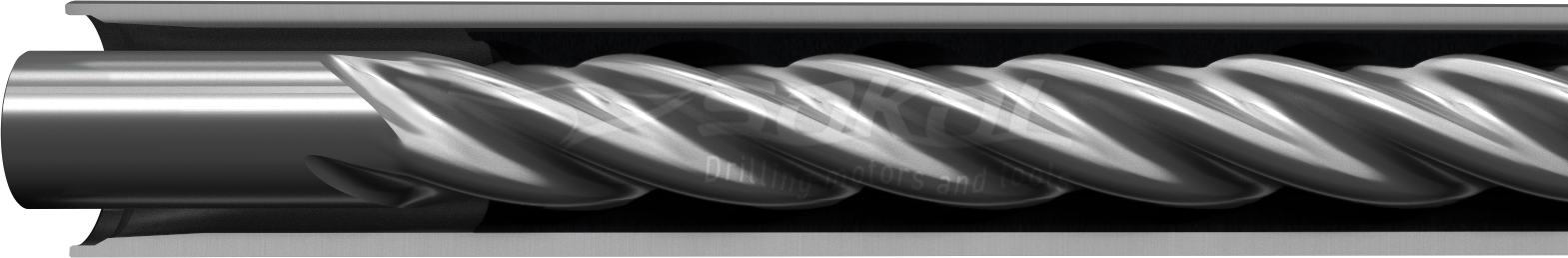

Elastomers & rotor coatings

SOKOL Drilling motors and tools has developed Nitrile Butadiene Rubber (NBR) for standard requirements and also Hard Rubber (HR) for higher torque requirements. Stators with Oil-Resistant Elastomer (S) are recommended for oil-base muds while High-Temperature Elastomer (T) stator can be utilized at temperatures up to 180°C. In cooperation with Russian Academy of Sciences we formulated new math models which help us select fit-for-purpose elastomer compounds and injection parameters. Rubber compounds are manufactured and supplied by the leading German and American rubber manufacturers with high physical and mechanical properties.

| Properties | Value | |

| Density, kg/m3, max | 1500 | |

| Sand, %, max | 1 | |

| Chlorides, kg/m3, max | 50* | |

| Oil content, % | Conventional (N) stator, hard rubber (HR) stator, high-temperature stator (T) | 10 |

| Oil-resistant stator (S) | 100** | |

| Temperature (dynamic downhole), ºC, max: | Conventional (N), hard rubber (HR) stator, oil-resistant (S) stator | 120** |

| High-temperature stator (T) | 180** | |

* - higher chlorides content requires a special coating on the rotor (may be custom-made).

** – temperature- and oil-resistant stators may be custom-made.

Chlorides in mud can severely corrode chrome plating on rotors and, as a result, deteriorate stator elastomer. Certain additives in mud can have a detrimental effect on mechanical properties of the stator elastomer and severly reduce the life of the stator.

in Solutions of Various Densities (at 15ºС)

| Mass concentration, % | NACL | KCL | ||||

| Density, kg/m3 | Salt content, kg/m3 | Chloride ion content, kg/m3 | Density, kg/m3 | Salt content, kg/m3 | Chloride ion content, kg/m3 | |

| 1 | 1 006 | 9 | 5 | 1 002 | 11 | 5 |

| 2 | 1 012 | 17 | 10 | 1 010 | 20 | 10 |

| 3 | 1 018 | 26 | 16 | 1 016 | 30 | 14 |

| 4 | 1 030 | 46 | 28 | 1 022 | 40 | 19 |

| 5 | 1 036 | 54 | 33 | 1 028 | 51 | 24 |

| 6 | 1 042 | 63 | 38 | 1 035 | 63 | 30 |

| 7 | 1 054 | 83 | 50 | 1 041 | 73 | 35 |

| 8 | 1 060 | 91 | 55 | 1 048 | 83 | 40 |

| 9 | 1 066 | 100 | 61 | 1 055 | 94 | 45 |

| 10 | 1 072 | 108 | 66 | 1 061 | 106 | 50 |

| 11 | 1 078 | 117 | 71 | 1 068 | 117 | 56 |

| 12 | 1 090 | 134 | 81 | 1 074 | 128 | 61 |

| 13 | 1 093 | 139 | 84 | 1 082 | 141 | 67 |

| 14 | 1 096 | 144 | 87 | 1 089 | 154 | 73 |

| 15 | 1 099 | 149 | 90 | 1 095 | 165 | 79 |

| 16 | 1 120 | 184 | 112 | 1 102 | 177 | 84 |

| 17 | 1 126 | 194 | 118 | 1 109 | 190 | 90 |

| 18 | 1 138 | 211 | 128 | 1 116 | 203 | 97 |

| 19 | 1 144 | 221 | 134 | 1 123 | 214 | 102 |

| 20 | 1 150 | 231 | 140 | 1 131 | 225 | 107 |

| 21 | 1 162 | 251 | 152 | 1 138 | 238 | 113 |

| 22 | 1 168 | 261 | 158 | 1 145 | 251 | 119 |

| 23 | 1 174 | 271 | 164 | 1 153 | 265 | 126 |

| 24 | 1 186 | 291 | 177 | 1 161 | 280 | 133 |

| 25 | 1 192 | 301 | 183 | - | - | - |

| 26 | 1 198 | 311 | 189 | - | - | - |

Rotors can be chrome plated in acc. with HEEF-25 process, or HVOF / HVAF tungsten carbide coated with ceramic sealing for maximum wear and erosion protection.

| Coating | Life, hours | |

| Normal mud | Salt-saturated mud | |

| Chrome plating HEEF-25 | 250...300 | 50...70 |

| Unplated stainless steel | 150…200 | 130…150 |

| Chrome plating with subsequent ceramic densification | 450...500 | 350…400 |

| Tungsten carbide coating applied by HVOF / HVAF with subsequent ceramic densification | 1000…1500 | 1000…1500 |

| Wear-resistant coatings with subsequent fusion process | 700…750 | 700…750 |