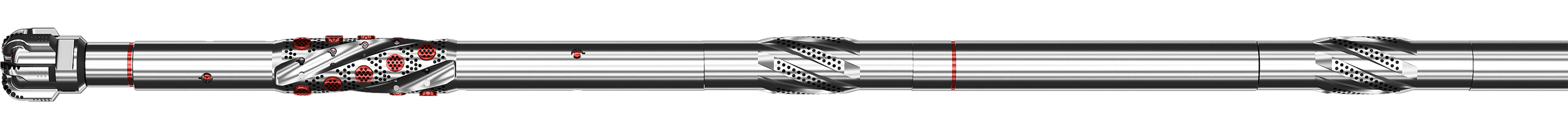

ADJUSTABLE GAUGE STABILIZER

ADJUSTABLE GAUGE STABILIZER

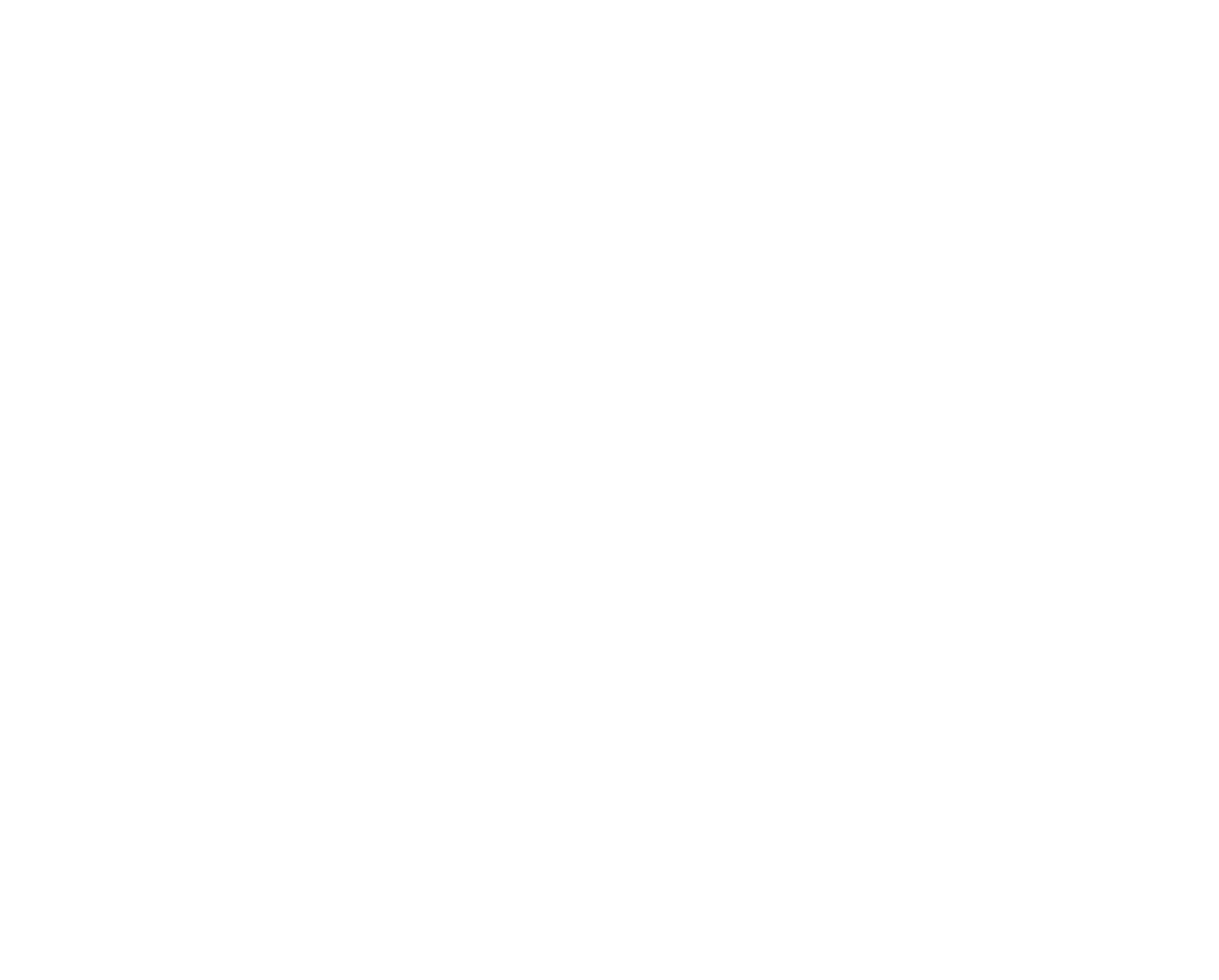

The AGS-SOKOL is a simple and reliable tool recently developed by SOKOL for correcting inclination in both rotary and motor based bottom hole assemblies.

The AGS-SOKOL is three (two as an option) positional and operated from surface by means of reducing and then increasing pump flow. No weight has to be applied to the string to move the tool from one position to the other. AGS-SOKOL is hydraulically actuated and it is ideal for running above or below motors, the blade change being carried out without fear of stalling the motor or damaging the PDC bit. In addition, the AGS-SOKOL has a nominal pressure loss and does not compromise bit hydraulics when being run in either rotary or motor based bottom hole assemblies.

Installation of AGS-SOKOL as first string stabilizer provides build up in the closed position (retracted) and slight drop off in the open position (extended).

AGS-SOKOL installed 1.5-4.6 m above the full gage near-bit stabilizer helps to change inclination in rotary drilling from 1.5°/30 m (build up) to — 0.6°/30 m (drop off). So directional driller is able to control the well trajectory without wasting time for round trip to change the string stabilizer.

Build up/drop off rate depends on the distance between the near-bit stabilizer and AGS-SOKOL. Aggressive rates may be reached by decreasing this distance.

Behaviour of BHA with AGS-SOKOL in any mode is the same as regular, which allows to combine two BHA types in one. As a result, we get smoother build up trajectory and cost reduction by decreasing number of round trips.

| Bottomhole assembly | Build up rate (°/30 m), in the following modes: "closed" (non-zero)/ "open" (zero) | |||||||||

| 152.4 mm | 215.9 mm | 311.1 mm | 444.5 mm | |||||||

| AGS-SOKOL = first string stabilizer | 142.9 | 152.4 | 196.8 | 203.2 | 215.9 | 292.1 | 298.4 | 311.1 | 425.4 | 444.5 |

| Bit-Full-gage stab-DC 1.5 m — AGS-SOKOL(AGS-SKL)-MWD-Full-gage stab | +1.30 | -0.40 | +1.50 | +1.00 | -0.40 | +1.50 | +1.00 | -0.40 | +1.00 | -0.40 |

| Bit-Full-gage stab-DC 3 m-AGS-SKL-MWDFull-gage stab | +1.00 | -0.20 | +0.75 | +0.50 | -0.20 | +1.25 | +0.50 | -0.20 | +0.50 | -0.20 |

| Bit-Full-gage stab-DC 4.6 m — AGS-SKLMWD-Full-gage stab | +1.25 | +0.20 | +0.60 | +0.20 | -0.40 | +0.60 | +0.20 | -0.40 | +0.40 | -0.60 |

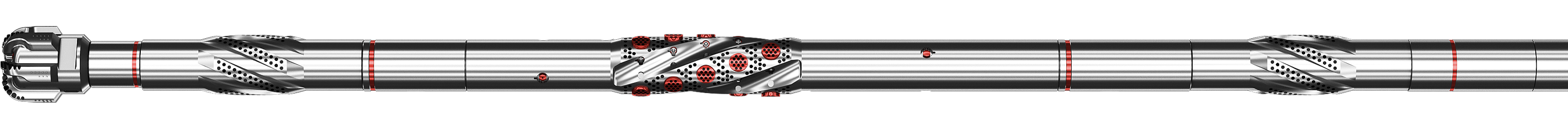

Recently AGS-SOKOL has been used as a rotating near-bit stabilizer right below the motor. Now this BHA is commonly used for horizontal wells with size 165.1 and smaller.

The tool is placed right above the bit and torqued to lower box of the motor. Full gage mode of the stabilizer is set to the size 3mm less than wellbore (bit) diameter. Motor may be equipped with bearing section stabilizer. Third stabilizer is installed 4.9 — 6.1m above in the drill string, this distance is defined by position of connection point of motors with twin power section.

Unplanned corrections of azimuth in horizontal wells are very rare. AGS-SOKOL allows to set a zero bend angle and achieve higher ROP with fast correction of inclination. Use of the tool below the motor provides build up rate up to +1,4°/30 m in open mode (extended) and drop off rate up to — 2,5°/30 m in "closed" mode (retracted).

Sections with small radius of hole curvature are commonly drilled with bits with increased diameter to support drillability of the wellbore with rigid BHA components (e.g., to drill 155.6 and 165.1mm sections of the well bits with diameters 165.1 and 171.4mm accordingly). Field test data have proven that the stabilizer passes through the sections with curvature up to 22°/30m.

| Bottomhole assembly | Build up rate (°/30 m), in the following modes: "closed" (non-zero)/ "open" (zero) | |||||||||

| 152.4 mm | 215.9 mm | 311.1 mm | 444.5 mm | |||||||

| AGS-SOKOL = first string stabilizer | 142.9 | 152.4 | 196.8 | 203.2 | 215.9 | 292.1 | 298.4 | 311.1 | 425.4 | 444.5 |

| Bit-AGS-SKL-DC 3.0 m-Full-gage stabMWD-Full-gage stab | -1.25 | -0.20 | +1.30 | -1.25 | -0.40 | -1.25 | -1.25 | -0.40 | -1.00 | -0.40 |

| Bit-AGS-SKL-6.4 mm DC 3.0 m-Full-gage stab-MWD-Full-gage stab | -1.00 | +0.20 | -1.00 | -1.00 | +0.30 | -1.20 | -1.20 | 0 | -1.20 | 0 |

| Bit-AGS-SKL-3.0 mm DC 12.7 m-Full-gage stab-MWD-Full-gage stab | -0.60 | +1.00 | -1.60 | -1.60 | +0.60 | -1.00 | -1.00 | +0.50 | -1.20 | +0.50 |

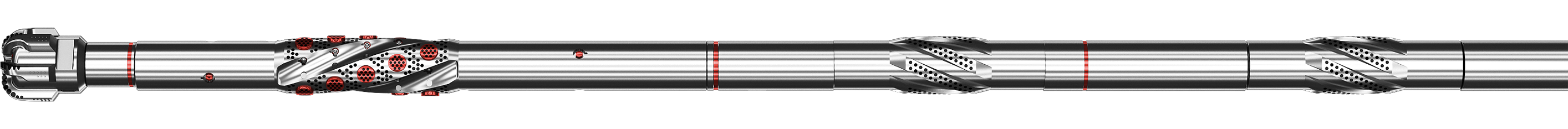

About one quarter of the BHA with AGS-SOKOL are BHA where AGS-SOKOL is placed above the motor. According to research results 90% of time for hold sections drilling in sliding mode is spent on correction of inclination.

DRILLING OF HOLD SECTIONS Cost advantage of AGS-SOKOL installation above the motor is decreasing time for inclination correction. In this case changes of wellbore geometry are made by changing mode of operation of AGS-SOKOL during rotary drilling. This decreases sliding time. As a result we get faster ROP, cleaner hole and better wellbore quality as we eliminate violent geometry changes due to multiple orientations with motor.

DRILLING OF HORIZONTAL WELLS Increase of inclination angle leads to increase of BHA aggressivity. In some cases AGS-SOKOL is enough to make 6 the required inclination corrections, so installation of straight motor is possible.

| Size of well, mm | AGS-SKL size range, mm | Distance from AGS-SKL to bearing section, m | Rate of inclination change, °/30m | |

| "closed" mode (non-zero) | "open" mode (zero) | |||

| 444.5 | 425.4 — 444.5 | 9.1 — 10.1 | +0.30 | -0.40 |

| 406.4 | 387.3 — 406.4 | 9.1 — 10.1 | +0.30 | -0.40 |

| 311.1 | 298.4 — 311.1 | 8.5 — 9.4 | +0.30 | -0.30 |

| 292.1 — 311.1 | 7.9 — 8.8 | +0.50 | -0.50 | |

| 215.9 | 203.2 — 215.9 | 7.9 — 8.8 | +0.30 | -0.20 |

| 196.8 — 215.9 | 7.3 — 8.2 | +0.40 | -0.40 | |

| 152.4 | 142.9 — 152.4 | 6.1 — 6.7 | +0.30 | -0.40 |

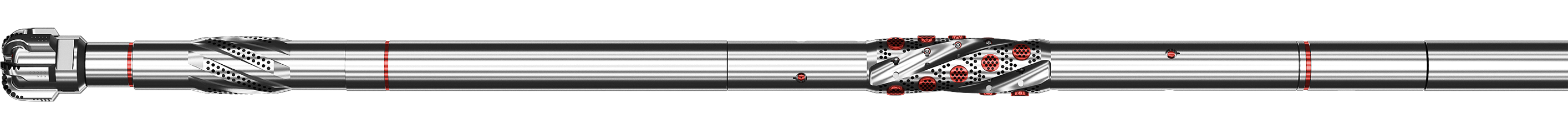

Recently AGS-SOKOL has been used as a rotating near-bit stabilizer right below the motor. Now this BHA is commonly used for horizontal wells with size 165.1 and smaller.

The tool is placed right above the bit and torqued to lower box of the motor. Full gage mode of the stabilizer is set to the size 3mm less than wellbore (bit) diameter. Motor may be equipped with bearing section stabilizer. Third stabilizer is installed 4.9 — 6.1m above in the drill string, this distance is defined by position of connection point of motors with twin power section.

Unplanned corrections of azimuth in horizontal wells are very rare. AGS-SOKOL allows to set a zero bend angle and achieve higher ROP with fast correction of inclination. Use of the tool below the motor provides build up rate up to +1,4°/30 m in open mode (extended) and drop off rate up to — 2,5°/30 m in "closed" mode (retracted).

Sections with small radius of hole curvature are commonly drilled with bits with increased diameter to support drillability of the wellbore with rigid BHA components (e.g., to drill 155.6 and 165.1mm sections of the well bits with diameters 165.1 and 171.4mm accordingly). Field test data have proven that the stabilizer passes through the sections with curvature up to 22°/30m

| Size of well, mm | AGS-SKL size range, mm | Size of bearing section, mm | Size of first string stabilizer, mm | Rate of inclination change, °/30m | |

| "closed" mode (non-zero) | "open" mode (zero) | ||||

| 149.2 | 136.5 — 146.0 | 133.3 | 127.0 | -2.50 | +1.40 |

| 155.6 | 142.9 — 152.4 | 139.7 | 133.3 | -2.50 | +1.40 |

| 215.9 | 203.2 — 215.9 | — | 203.2 | -1.00 | +0.50 |

| 311.1 | 292.1 — 311.1 | — | 308.0 | -1.20 | +0.80 |